About Us

About SHUTER

SHUTER was founded in 1969 and is a manufacturer in Taiwan to provide industrial storage solutions. SHUTER Enterprise was developed in Taiwan by family owned and operated, over the decades, this proudly Taiwanese brand SHUTER has become a world-class supplier of sleek and practical office and industrial storage solutions. Today, SHUTER headed by second generation chairman and storage design innovator Yira Wu.

From over 50 years experiences, SHUTER controls the key productions and know-how step by step. No matter the materials purchasing or products sales, every segment is under our deliberate consideration and plan. In order to keep our advantage in the market, what did we do?

SHUTER's Brands

SHUTER Enterprise created our brands, which are for different product lines. Brand SHUTER focuses on offering tool boxes, tool carts, tilt out bins, workbenches, lockers and metal cabinets as a workspace solution; and brand livinbox concentrates on providing the plastic storage boxes, containers and desktop organizers for stationery, crafts, sewing supplies and household storage and organizer. All products are made in our Babuzza Dreamfactory in Taiwan.6 Product Lines

SHUTER has 6 product lines to cover the most complete storage solutions, including stationery storage, household storage, office storage, industry storage, 3C accessories storage and healthcare storage. SHUTER manufactures metal lockers, tool cabinets, heavy duty shelves, tool carts, tool storage racks, workbenches, tool boxes, plastic storage bins, flip out bins, antistatic organizers, office file cabinets and so on.OEM, ODM And OBM Services

SHUTER is experienced on OEM, ODM, and OBM projects. We can take care of every stage of the manufacturing process, from product development and design, mold making and manufacturing to testing, quality control and packaging. You need to look no further than SHUTER to solve all your industrial storage needs caused by maintenance, repair and operations.Automated Storage and Retrieval System (ASRS)

SHUTER uses ASRS for automatically placing and retrieving our inventory loads. It allows for more storage space due to high-density storage and narrower aisles, furthermore, ASRS make our inventory more flexible and efficient.Production factory & Tourist factory

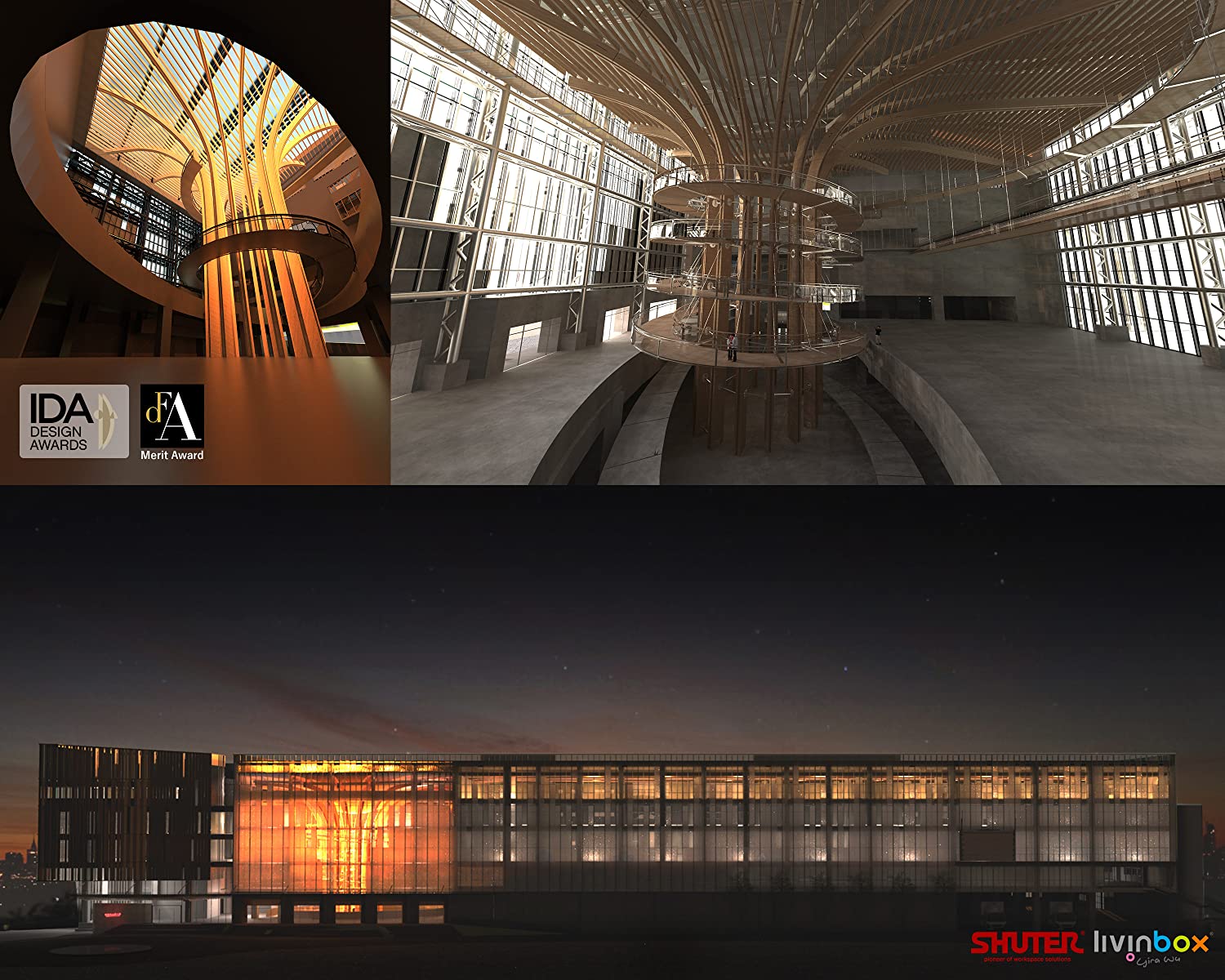

Our new plant named Babbuza Dreamfactory occupies a total area of more than 20,000 square meters and can produce over 800,000 items every month for corporate customers on every continent. SHUTER moved to new factory in the beginning of 2021 for our new page.What do we insist?

1. Protect earth

SHUTER uses non-toxic materials to pursue the ultimate quality and maximize product life cycle.2. Eco-friendly

We replace and renew our equipment to make production efficient for energy saving.3. Love Taiwan

All our products are 100% made in Taiwan, our factory locates in Taiwan only, SHUTER goals to introduce MIT products to the world.4. Social responsibility

SHUTER provide a friendly working environment and help disadvantaged groups positively. Compare to companies in Taiwan, we hire more disability employment than others.Our Mission

SHUTER devotes ourselves to the production of creative, innovative, and environmentally sustainable storage products for home and office spaces, and guarantee total customer satisfaction in these products.Our Commitment

SHUTER is dedicated to maintaining a management approach that is fully committed to upholding human rights and pursuing positive business practices. SHUTER actively creates and maintains a cheerful work environment, treating every colleague like a family member. SHUTER extends this commitment to a good quality of life into the wider community through various charitable endeavors.Our Vision

SHUTER is determined to one day see SHUTER listed among the world’s top 100 brands. However, we never forget our Taiwanese roots, and proudly print the words “Made in Taiwan” on all our products, no matter where our global ambitions take us.- Videos

.jpg?v=290c742a)

.jpg?v=43e34b29)

.jpg?v=91cb6fc9)

.jpg?v=da98bd3e)

.jpg?v=ecd58082)